KOH YOUNG TECHNOLOGY

TRC, is a full service manufacturers' representative that specializes in both benchtop and fully automatic 3D solder paste inspection systems and 3D AOI for printed circuit boards.

Technical Resources Corporation, or TRC, is a full service manufacturers’ representative that specializes in both benchtop and fully automatic 3D solder paste inspection systems and 3D AOI for printed circuit boards.

“8030-3” SPI and “Zenith” AOI Inspection Systems

Absolute Convenience

The KY 8030-3 inspection systems take the parametric inspection approach, in which the systems derive inspection results strictly based on the measured values of several parameters for each individual solder paste deposit. This allows any operator to program the system in less than ten minutes by setting up only inspection conditions.

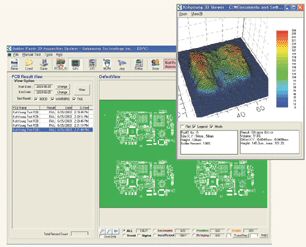

Highly Reliable and Accurate Inspection

Based on the 3D geometrical measurement data of each ROI (Region of Interest) on the PCBs with the solder paste on them, the 8030-3 is capable of detecting not only insufficient, excessive solder pastes, and shape deformity errors retaining 3D characteristics, but also cases of no paste, bridging, and position errors with 2D characteristics.

Inspection Systems that Consider Througput

On a typical application, the 8030-3 was able to inspect all solder paste on approximately 4,000 pads within 25 seconds. Users of the KY systems are able to systematically keep their screen printers in an optimal working condition by depending on the 3D shape analysis of solder paste on each pad, and changing the trend of the volume distribution of each PCB. As a result, you will be able to significantly improve the process capability, and reduce rework expenses and loss of expensive electrical devices

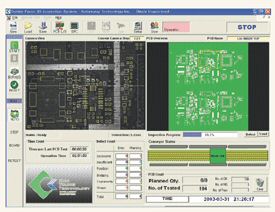

User-friendly Operating and Programming Screen

Most inspection equipment in the SMT field has taken the golden board inspection approach. The approach requires a large library of sufficient amount of image data that needs to be built during the programming stage. The data includes images of solder paste on pads considered exemplary by operators. During real-time inspection, the equipment inspects each object and concludes whether it matches the images in the previously developed library. Thus, developing such a library requires much time, effort, and knowledge.

Koh Young’s approach allows any operator to program the system in approximately ten minutes by setting up only inspection conditions. The user-friendly programming process requiring only a simple 30 minute training for the operator. Absolute user-friendliness is accomplished through a simple programming environment and the Gerber conversion software front-end

Clear and Easy Defect Review Window

All kinds of defects from screen printing processes can be detected through 3D inspection, which includes not only insufficient paste, excessive paste, shape deformity based on 3D volume and shape measurements, but also cases of no paste, bridging, and placement error. 3D shape diagnosis data are provided for customers to identify a specific set of solder pastes with normal volume but potential shape deformity.

KSMART Tools for Industry 4.0

The KSMART engine is powered by Artificial Intelligence that provides closed-loop insight for screen printer optimization and mount analysis optimization. Since 2009, Koh Young has been “leading the charge” with innovative closed-loop technologies, based on their history of working with the key suppliers for solder paste, screen printers and mounting equipment.

With Koh Young’s Real-Time SPC, …

.. the volume measurement repeatability data is collected. Sets of the SPC (Statistical Process Control) data are provided for customers to build the basis for six sigma quality management.Inspection reliability has been further ensured by applying an intelligent inspection algorithm particularly for eliminating various kinds of noise affecting the inspection process. Coupled with the latest “closed-loop” option, the Koh Young will communicate with the screen printer and make optimal changes “on-the-fly”

EMAIL US

Technical Resources Corporation also represents Universal Instruments’ pick and place machines, Kurtz Ersa selective soldering, wave soldering, reflow and rework systems, GPD Global Precision Dispensing systems, KIC thermal profiling systems, FlexLink laser markers and conveyors, Takaya Flying Probe In-Circuit test systems, Specialty Coating Systems Spray Coating & Dispense Systems, Aqua Klean Systems in-line cleaning systems, Austin American Technology batch & stencil cleaners, Nikon Metrology 3D X-Ray and CT Inspection Systems, LPMS USA low pressure moulding systems, Inovaxe innovative material handling solutions, KOKI soldering materials and Garland Service Company wave/conformal coat/SMT tooling.