KIC

TRC, is a full services manufacturers' representative which specializes in continuous process monitoring and thermal profiling systems for electronics manufacturing operations.

Technical Resources Corporation, or TRC, is a full services manufacturers’ representative which specializes in continuous process monitoring and thermal profiling systems for electronics manufacturing operations. KIC continues to set the standards and bringing “market firsts” to our industry, as seen below.

For over four decades now, KIC has advanced industries worldwide with their innovative technology firsts.

The timeline below highlights some of KIC’s numerous technological achievements….

- 2021 – “WPI”, Wave Process Inspection for automated dwell, parallelism, real-time Cpk, traceability & process control

- 2019 – “SRA”, Smart Reflow Analyzer; a “smart fixture” with integrated profiler utilizing laser technology for speed measurement and offering instant insight into reflow oven performance

- 2017 – “Vantage” Industry 4.0 Smart Factory Starter Kit for reflow/cure data management and analytics

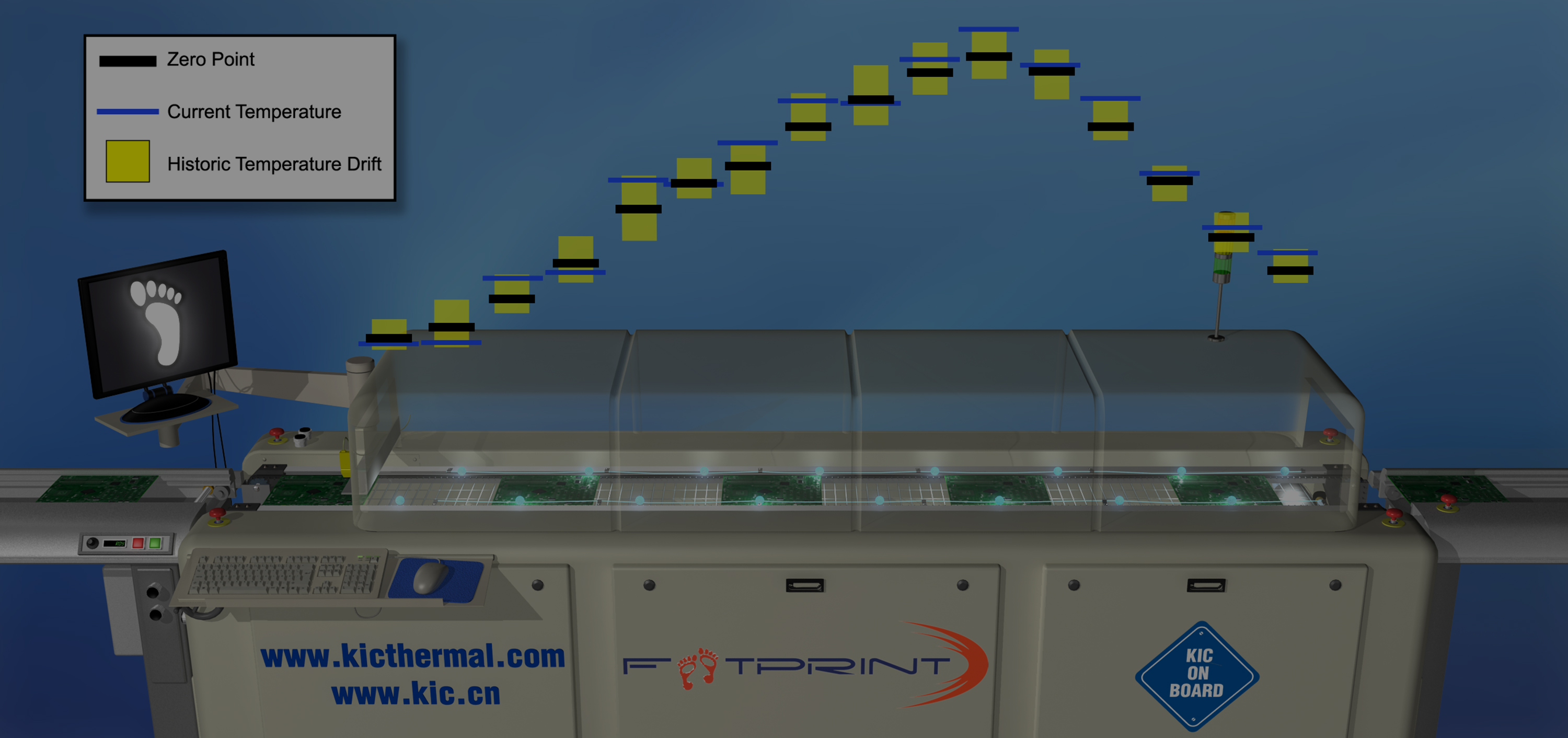

- 2016 – “Footprint”, a system that requires no profiling, no programming, no process spec limits

- 2014 – “RPI”, next generation realtime process monitoring system

- 2014 – SPS latest smart profiler introduced to market (full compatibility of all prior profiles)

- 2013 – X5 latest profiler with new “Profiling Software” platform

- 2012 – Probot automated profiling system and realtime monitoring

- 2010 – MVP, Manual Virtual Profile

- 2009 – all new “Wave Surfer” for automated wave soldering applications

- 2007 – KIC Explorer: newly designed, ultra-compact profiler

- 2006 – KIC Vision: automatic profiling system that automatically validates and creates new profile “on-the-fly”

- 2002 – KIC Auto-Focus: oven setup tool that automatically suggests an initial oven recipe for new products, with the potential for new product setup without having to run a verification profile.

- 2001 – KIC 24/7: the second generation continuous process control system that automatically provides production traceability and SPC charting, including Cpk, for every product that passes through the oven. The KIC 24/7 wins the SMT Vision Award.

- 2000 – KIC Pilot: an automated oven setup control software that enables a line operator with one hour of training to setup and optimize the reflow oven for a new boards. The KIC Pilot wins the SMT Vision Award, EP&P Excellence Award, and the EP&P Grand Excellence Award for the best new SMT assembly product of 2000.

- 1999 – KIC introduces the Process Window Index (PWI). The PWI is a statistical innovation that defines a profile’s fit to the process window in a single number.

- 1998 – KIC Auto-Predict: the first oven recipe “search engine” that automatically identifies the optimal oven setup.

- 1995 – KIC introduces WinKIC: the first Profiling software for Microsoft Windows. “Virtual Profiling”: continuously calculates the product profile for every board that passes through the oven.

- 1991 – SideKIC: the first wireless real-time pass-through profiler.

- 1989 – KIC introduces the first Profile Prediction software for microcomputers.

- 1977 – KIC introduces the first continuous monitoring system for conveyorized furnaces for microcomputers.

EMAIL US

Technical Resources Corporation also represents Universal Instruments’ pick and place machines, Kurtz Ersa selective soldering, wave soldering, reflow and rework systems, GPD Global Precision Dispensing systems, FlexLink laser markers and conveyors, Takaya Flying Probe In-Circuit test systems, Koh Young 3D AOI and SPI systems, Specialty Coating Systems Spray Coating & Dispense Systems, Aqua Klean Systems in-line cleaning systems, Austin American Technology batch & stencil cleaners, Nikon Metrology 3D X-Ray and CT Inspection Systems, LPMS USA low pressure moulding systems, Inovaxe innovative material handling solutions, KOKI soldering materials and Garland Service Company wave/conformal coat/SMT tooling.